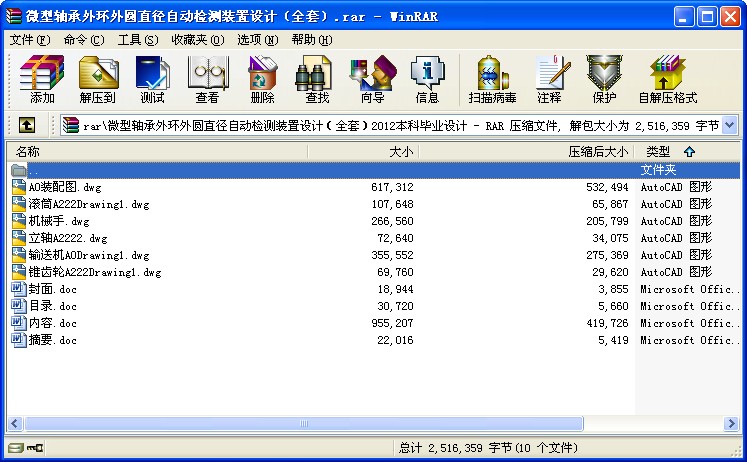

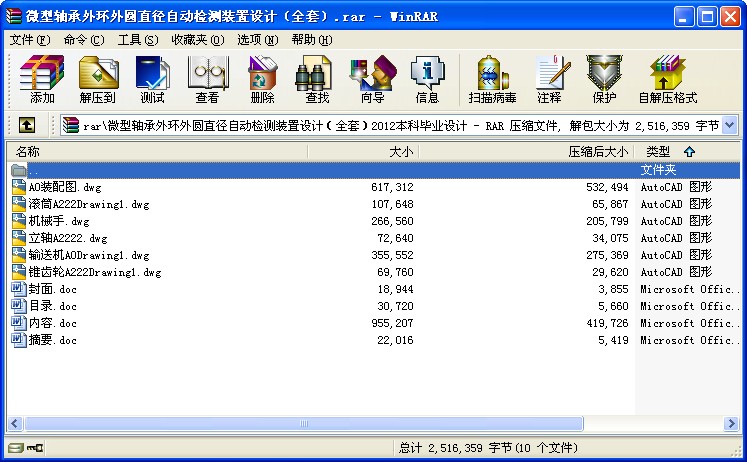

微型軸承外環(huán)外圓直徑自動檢測裝置設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 微型軸承外環(huán)外圓直徑自動檢測裝置設(shè)計(jì)

ABSTRACT

Bearing construction has a very important role in the national economy. One of the most widely used in various rotating machinery General machinery parts. Where mechanical components is a high degree of standardization of rolling bearings, friction small, starts easy, lubrication is simple, easy to change and so on, is almost indispensable parts in mechanical structure, was passed in the various mechanical movement and subjected to loads of important supporting parts. Bearing quality is good or bad impact on the safe operation of the equipment is very important, when assembling machinery guarantee the quality of your bearing and bearing parts in real time observations, has a very important significance.

This is the miniature bearing ring outer diameter measuring device of mechanical part design, detection part of the selection of a pair of electric Eddy current type sensors. Designed primarily for 635ZZ type of miniature bearing testing, package testing device automation, higher detection accuracy.

Main work principle is the feeder will be bearing pushed on to a conveyor belt, and belt driven walk, center line and when there is 32mm bearing machinery fingers go line coincident manipulator, when the bearing reaches the robot when the centre line conveyor belt stop robot crawling bearing to detection, detection by Eddy current sensor group.

Keywords:Belt conveyor;Manipulator;Bearing;Detection;Feeding machine

目 錄

摘要 ………………………………………………………………………………………Ⅰ

ABSTRACT…………………………………………………………………………………Ⅱ

第1章 緒 論……………………………………………………………………………1

1.1課題研究的目的意義……………………………………………………………1

1.2國內(nèi)外研究狀況…………………………………………………………………2

1.3設(shè)計(jì)內(nèi)容…………………………………………………………………………3

第2章 軸承的檢測……………………………………………………………………6

2.1軸承的基本結(jié)構(gòu)…………………………………………………………………6

2.2軸承檢測的內(nèi)容和檢測條件……………………………………………………7

2.2.1軸承檢測的標(biāo)準(zhǔn)…………………………………………………………7

2.2.2軸承檢測的內(nèi)容和檢測條件……………………………………………7

2.3測量用電渦流式傳感器…………………………………………………………9

2.4 本章小結(jié)…………………………………………………………………………9

第3章 微型軸承自動檢測線設(shè)計(jì)…………………………………………………10

3.1內(nèi)容簡介…………………………………………………………………………10

3.2總體方案的確定…………………………………………………………………10

3.2.1方案選擇…………………………………………………………………10

3.2.2設(shè)計(jì)要求…………………………………………………………………12

3.2.3各個(gè)聯(lián)系尺寸的確定……………………………………………………12

3.2.4輸送線工作循環(huán)周期……………………………………………………13

3.2.5電動機(jī)選擇………………………………………………………………14

3.3本章小結(jié)…………………………………………………………………………15

第4章 輸送機(jī)設(shè)計(jì)……………………………………………………………………16

4.1帶式輸送機(jī)簡介…………………………………………………………………16

4.1.1輸送機(jī)的發(fā)展……………………………………………………………16

4.1.2輸送機(jī)工作原理…………………………………………………………16

4.1.3帶式輸送機(jī)的優(yōu)點(diǎn)………………………………………………………17

4.2輸送機(jī)各部分的設(shè)計(jì)……………………………………………………………17

4.2.1機(jī)架的設(shè)計(jì)………………………………………………………………17

4.2.2帶的選擇…………………………………………………………………17

4.2.3驅(qū)動裝置的設(shè)計(jì)…………………………………………………………19

4.2.4拉緊裝置的選擇設(shè)計(jì)……………………………………………………21

4.2.5滾筒設(shè)計(jì)…………………………………………………………………21

4.2.6托輥的選擇………………………………………………………………23

4.3本章小結(jié)…………………………………………………………………………24

第5章 上料裝置設(shè)計(jì)…………………………………………………………………25

5.1概述………………………………………………………………………………25

5.2上料裝置的設(shè)計(jì)…………………………………………………………………25

5.2.1電動機(jī)的選擇……………………………………………………………25

5.2.2軸的設(shè)計(jì)…………………………………………………………………25

5.2.3齒輪的設(shè)計(jì)………………………………………………………………26

5.2.4各部分零件的校核………………………………………………………28

5.3本章小結(jié)…………………………………………………………………………33

第6章 機(jī)械手的設(shè)計(jì)…………………………………………………………………34

6.1概述………………………………………………………………………………34

6.2基本尺寸的確定…………………………………………………………………34

6.3液壓缸結(jié)構(gòu)的設(shè)計(jì)………………………………………………………………36

6.3.1主要部件結(jié)構(gòu)選擇………………………………………………………36

6.3.2液壓缸主要尺寸的確定…………………………………………………37

6.3.3各部件的聯(lián)接結(jié)構(gòu)設(shè)計(jì)…………………………………………………39

6.4本章小結(jié)…………………………………………………………………………40

結(jié)論………………………………………………………………………………………41

參考文獻(xiàn)…………………………………………………………………………………42

致謝………………………………………………………………………………………44

...