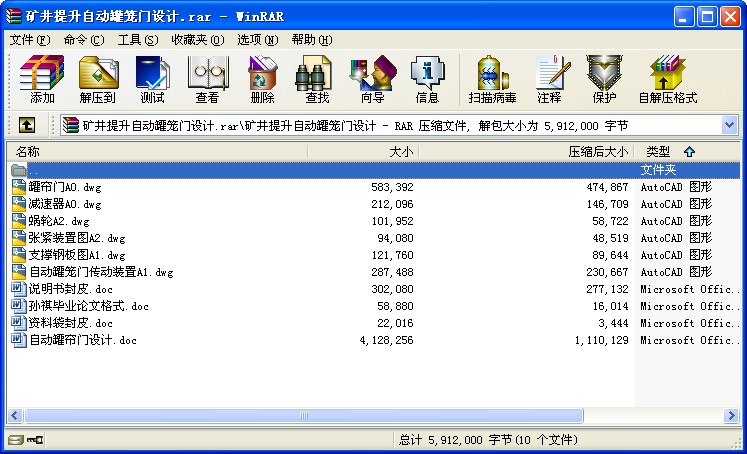

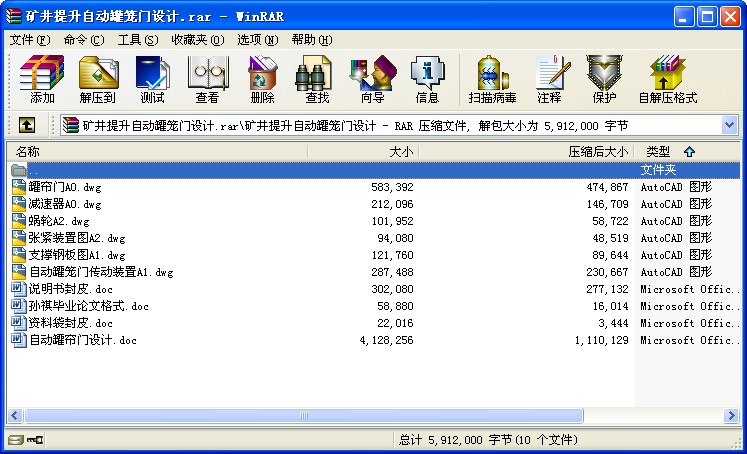

礦井提升自動(dòng)罐籠門設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 礦井提升自動(dòng)罐籠門設(shè)計(jì)

摘 要

煤炭被人們譽(yù)為黑色的金子,工業(yè)的食糧,它是十八世紀(jì)以來(lái)人類世界使用的主要能源之一。在礦井系統(tǒng)中,提升機(jī)是不可或缺的主要設(shè)備之一,而保障礦井提升機(jī)的安全運(yùn)作更是煤礦生產(chǎn)的重中之重。針對(duì)礦用罐籠門原理和結(jié)構(gòu)上的弊端,目前,一種基于無(wú)極繩的自動(dòng)罐籠門應(yīng)運(yùn)而生。該設(shè)備是由PLC通過(guò)對(duì)外部動(dòng)力機(jī)制和無(wú)極繩牽引的控制,達(dá)到在提升過(guò)程中的安全閉鎖。該系統(tǒng)具有簡(jiǎn)單的結(jié)構(gòu),靈活、可靠的操作和高度的自動(dòng)化。此外,該設(shè)備安全,結(jié)構(gòu)緊湊,適合廣泛的應(yīng)用。

作為一個(gè)多用途籠吊提升裝置,罐籠不僅能提升人員、各類用于地下的機(jī)械和電氣設(shè)備,也可以轉(zhuǎn)移在礦井提升系統(tǒng)的材料和礦物質(zhì)。在特殊時(shí)間提升人員時(shí),必須確保人身安全,所以提升罐籠的出入口必須安裝安全的罐籠,要求是安全、可靠和易于使用。雖然罐籠的結(jié)構(gòu)經(jīng)歷了數(shù)次改善,罐籠的設(shè)計(jì)理念依舊保持強(qiáng)調(diào)安全性,其舒適性和用戶滿意度都被忽略。為了保障其安全性和舒適性,同時(shí)提高自動(dòng)化程度,減少體力勞動(dòng)強(qiáng)度,一種基于無(wú)極繩的新型自動(dòng)罐籠門應(yīng)運(yùn)而生。

基于無(wú)極繩的自動(dòng)罐籠門結(jié)構(gòu)的設(shè)備是在PLC對(duì)外部動(dòng)力交換機(jī)的核心和無(wú)極繩運(yùn)動(dòng)的整體程序控制基礎(chǔ)上進(jìn)行的閉環(huán)傳遞,從而達(dá)到罐籠門在提升過(guò)程中安全封鎖的目的。

關(guān)鍵詞:無(wú)極繩; 罐籠門; 可編程邏輯控制器。

ABSTRACT

The coal was hailed as the black gold, food industry, it is one of the main energy of the human world in the 18th century. Mine system, the elevator is one of the indispensable equipment, to protect the mine to enhance the safe operation of the machine is a top priority of mine production.Aiming at the disadvantages of cage door’s principle and structure used in mine, at present, a type of automatic cage door based on endless rope is designed. The equipment is controlled by PLC with mechanism of external motive force switch and traction by endless rope, which achieves safe blocking in the hoisting process of cage door. The system has simple structure, flexible and reliable operation and high degree of automation. In addition, the equipment is also safe, shapely and comfortable with a wide range of practical.

As a multi-purpose cage hoisting container, the cage not only can hoist personnel, various types of mechanical and electrical equipment for use underground, but also can transfer materials and minerals in mine shaft hoisting system. When lifting personnel in particular must ensure the personal safety, so the safety cage must be installed for lifting cage’s entrances and exits, the request is safe, reliable and easy to use. Although the cage of the structure has experienced several improvements, the cage’s design concept is keeping emphasizing the safety, and its comfort and user-friendly are ignored. A type of new automatic cage door based on endless rope is designed in order to protect the safety and comfort, increase the degree of automation and reduce manual labor intensity.

The device of the structure of automatic cage door based on endless rope is based on PLC for the overall program’s control of the core with external motive force switch and endless rope exercise closed loop passing, which achieves to safe blocking in the lifting process of cage door.

Keywords: endless rope ; cage door ; PLC.

目 錄

1 緒 論 1

2 自動(dòng)罐簾門門型部分的分析及初步設(shè)計(jì) 2

3 對(duì)簾門機(jī)械傳動(dòng)部分的設(shè)計(jì)與計(jì)算及強(qiáng)度校核 4

3.1桿的強(qiáng)度校核: 4

3.1.1主動(dòng)桿的強(qiáng)度校核 4

3.1.2 從動(dòng)桿及兩端的角鋼 6

3.1.3 門簾桿的總重量的計(jì)算 7

3.2 無(wú)極繩及聯(lián)結(jié)件的選擇 8

3.2.1 鋼絲繩夾: 8

3.2.2無(wú)極繩鋼絲繩得最大伸長(zhǎng)量得計(jì)算: 9

3.2.3懸掛鋼絲繩的選擇: 9

3.2.4 滑輪的選型: 9

3.2.5 鋼絲繩與滑輪的摩擦力的計(jì)算: 10

3.3滑道的強(qiáng)度校核 11

3.4 受軸向載荷緊螺栓連接(靜載荷)強(qiáng)度校核與設(shè)計(jì) 13

3.5 電動(dòng)機(jī)的選擇 14

4 蝸輪蝸桿減速器進(jìn)行選型計(jì)算 17

4.1減速器總體設(shè)計(jì) 17

4.1.1減速器概述 17

4.1.2減速器設(shè)計(jì) 17

4.2阿基米德蝸桿蝸輪蝸桿的設(shè)計(jì)計(jì)算(參考《機(jī)械設(shè)計(jì)》) 17

4.2.1蝸桿傳動(dòng)概述 17

4.2.2蝸桿傳動(dòng)的失效形式 18

4.2.3蝸桿傳動(dòng)的材料選定 18

4.2.4確定傳動(dòng)比 19

4.2.5傳動(dòng)裝置運(yùn)動(dòng)參數(shù)的計(jì)算 19

4.2.6蝸桿傳動(dòng)的結(jié)構(gòu) 20

4.2.7蝸桿傳動(dòng)的主要參數(shù)和幾何尺寸計(jì)算 21

4.3蝸桿傳動(dòng)的潤(rùn)滑 24

4.4 蝸桿軸的設(shè)計(jì)計(jì)算 24

4.5蝸輪軸系設(shè)計(jì) 31

4.6鍵的選擇及強(qiáng)度校核 36

4.7軸承的選擇及強(qiáng)度校核 36

4.8蝸桿軸上軸承的選擇及強(qiáng)度校核 37

4.9蝸輪軸上軸承的選擇及強(qiáng)度校核 41

4.10減速器其他部件的設(shè)計(jì) 44

4.10.1通氣器 44

4.10.2油標(biāo) 44

4.10.3減速器箱體的設(shè)計(jì) 44

5 自動(dòng)罐籠門附屬裝置的設(shè)計(jì) 48

5.1計(jì)算軸承工作在中等沖擊時(shí)的壽命 48

5.2圓柱螺旋彈簧的設(shè)計(jì)計(jì)算 49

5.2.1確定彈簧絲直徑d 49

5.2.2確定彈簧有效圈數(shù)n 49

5.2.3 彈簧的幾何尺寸計(jì)算 50

5.2.4滑輪在滑道上的安裝位置計(jì)算 51

結(jié) 論 52

參考文獻(xiàn) 53

翻譯部分

英文原文 54

中文譯文 61

致 謝 66 ...

熱門關(guān)鍵詞:

熱門關(guān)鍵詞:

豫公網(wǎng)安備 41072402000322號(hào)

豫公網(wǎng)安備 41072402000322號(hào)