夾板五工位連續(xù)式復合模設計

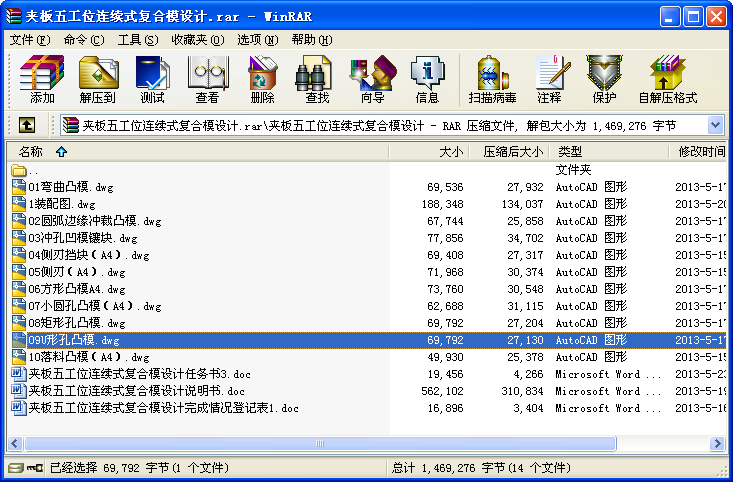

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 夾板五工位連續(xù)式復合模設計

摘 要

近年來,我國家電工業(yè)的高速發(fā)展對模具工業(yè),尤其是冷沖模具提出了越來越高的要求,十一五以來,冷沖模具在整個模具行業(yè)中所占比例已大大上升,據有關專家預測,在未來幾年中,中國冷沖模具工業(yè)還將持續(xù)保持年均增長速度達到15%左右的較高速度的發(fā)展。

沖壓成型是金屬成型的一種重要方法,它主要適用于材質較軟的金屬成型,可以一次成型形狀復雜的精密制件。本課題就是將石化、化工、電力等行業(yè)的法蘭密封結構中的墊片作為設計模型,將冷沖模具的相關知識作為依據,闡述冷沖模具的設計過程。

本設計對墊片進行的連續(xù)(級進)復合模模設計,利用Auto CAD及Pro-E軟件對制件進行設計繪圖。明確了設計思路,確定了沖壓成型工藝過程并對各個具體部分進行了詳細的計算和校核。如此設計出的結構可確保模具工作運用可靠,保證了與其他部件的配合。并繪制了模具的裝配圖和零件圖。

本課題通過對墊片的沖壓模具設計,鞏固和深化了所學知識,取得了比較滿意的效果,達到了預期的設計意圖。

關鍵字:沖壓模具;沖壓成型;連續(xù)模;模具設計

Abstract

In recent years, the rapid development of China\u0026#39;s household electrical appliance industry of mold industry, especially Die with the increasing demands put forward, since the Eleventh Five, Die in the proportion of the entire mold industry has been greatly increased, according to the experts forecast in the next few years, China will continue to maintain industrial Die average annual growth rate reached 15% of the high rate of development.

Stamping is an important method of metal forming, it is mainly applied to relatively soft metal forming, can be a molding of precision parts of complex shape. This topic is to petrochemical, chemical, electric power industries in the flange gasket sealing structure as a design model, Die related knowledge as a basis to explain the design process of Die.

The design of the gasket of the continuous (progressive) compound mode design, the use of Auto CAD software to design parts drawing. A clear idea of \u200b\u200bthe design to determine the metal forming process and the various specific parts of a detailed calculation and verification. The structure of such a design die is used to ensure reliability, ensure coordination with other components. And the mapping of the mold assembly and part drawings.

Through this project gasket stamping die design, consolidate and deepen the knowledge, and achieved satisfactory results, to achieve the desired design intent.

Key words: Stamping die; stamping molding; progressive die; die design

Abstract

In recent years, the rapid development of China\u0026#39;s household electrical appliance industry of mold industry, especially Die with the increasing demands put forward, since the Eleventh Five, Die in the proportion of the entire mold industry has been greatly increased, according to the experts forecast in the next few years, China will continue to maintain industrial Die average annual growth rate reached 15% of the high rate of development.

Stamping is an important method of metal forming, it is mainly applied to relatively soft metal forming, can be a molding of precision parts of complex shape. This topic is to petrochemical, chemical, electric power industries in the flange gasket sealing structure as a design model, Die related knowledge as a basis to explain the design process of Die.

The design of the gasket of the continuous (progressive) compound mode design, the use of Auto CAD software to design parts drawing. A clear idea of \u200b\u200bthe design to determine the metal forming process and the various specific parts of a detailed calculation and verification. The structure of such a design die is used to ensure reliability, ensure coordination with other components. And the mapping of the mold assembly and part drawings.

Through this project gasket stamping die design, consolidate and deepen the knowledge, and achieved satisfactory results, to achieve the desired design intent.

Key words: Stamping die; stamping molding; progressive die; die design

Abstract

In recent years, the rapid development of China\u0026#39;s household electrical appliance industry of mold industry, especially Die with the increasing demands put forward, since the Eleventh Five, Die in the proportion of the entire mold industry has been greatly increased, according to the experts forecast in the next few years, China will continue to maintain industrial Die average annual growth rate reached 15% of the high rate of development.

Stamping is an important method of metal forming, it is mainly applied to relatively soft metal forming, can be a molding of precision parts of complex shape. This topic is to petrochemical, chemical, electric power industries in the flange gasket sealing structure as a design model, Die related knowledge as a basis to explain the design process of Die.

The design of the gasket of the continuous (progressive) compound mode design, the use of Auto CAD software to design parts drawing. A clear idea of \u200b\u200bthe design to determine the metal forming process and the various specific parts of a detailed calculation and verification. The structure of such a design die is used to ensure reliability, ensure coordination with other components. And the mapping of the mold assembly and part drawings.

Through this project gasket stamping die design, consolidate and deepen the knowledge, and achieved satisfactory results, to achieve the desired design intent.

Key words: Stamping die; stamping molding; progressive die; die design

目 錄

中文摘要 Ⅰ

英文摘要 Ⅱ

1 緒論 5

1.1 引言 5

1.2 模具行業(yè)的發(fā)展現(xiàn)狀和市場前景 5

1.3 沖壓工藝介紹 6

1.4 沖壓工藝的種類 6

2 沖裁件的工藝分析 8

2.1 工件材料 8

2.2 工件結構形狀 8

2.3 工件尺寸精度 8

3 沖裁工藝方案的確定 9

4 模具結構形式的確定 11

5 模具總體設計 12

5.1 模具類型的選擇 12

5.2 操作方式 12

5.3 卸料、出件方式 12

5.4 確定送料方式 12

5.5 確定導向方式 12

6 模具設計計算 14

6.1 排樣、計算條料寬度、確定步距、材料利用率 14

6.2 沖壓力的計算 17

6.3 壓力中心的確定 19

6.4 模具刃口尺寸的計算 21

7 主要零部件設計 24

7.1 工作零部件的結構設計 24

7.2 卸料部件的設計 26

7.3 模架以及其他零部件的選用 26

8 校核模具閉合高度及壓力機有關參數 28

8.1 校核模具閉合高度 28

8.2 沖壓設備的選定 28

9 設計并繪制模具總裝圖及選取標準件 29

10 模具的安裝調試 30

10.1 模具的安裝調試 30

參考文獻 31

致 謝 32

1 緒論

1.1 引言

模具,做為高效率的生產工具的一種,是工業(yè)生產中使用極為廣泛與重要的工藝裝備。采用模具生產制品和零件,具有生產效率高,可實現(xiàn)高速大批量的生產;節(jié)約原材料,實現(xiàn)無切屑加工;產品質量穩(wěn)定,具有良好的互換性;操作簡單,對操作人員沒有很高的技術要求;利用模具批量生產的零件加工費用低;所加工出的零件與制件可以一次成形,不需進行再加工;能制造出其它加工工藝方法難以加工、形狀比較復雜的零件制品;容易實現(xiàn)生產的自動化的特點。

研究和發(fā)展模具技術,對于促進國民經濟的發(fā)展具有特別重要的意義,模具技術已成為衡量一個國家產品制造技術的重要標志之一,隨著工業(yè)生產的迅速發(fā)展,模具工業(yè)在國民經濟中的地位日益提高,并在國民經濟發(fā)展過程中發(fā)揮越來越大的作用。

設計出正確合理的模具不僅能夠提高產品質量、生產率、模具使用壽命,還可以提高產品經濟效益。在進行模具設計時,必須清楚零件的加工工藝,設計出的零件要能加工、易加工。充分了解模具各部件作用是設計者進行模具設計的前提,新的設計思路必然帶來新的模具結構。

...

文檔留言 共有條評論

熱門關鍵詞:

熱門關鍵詞:

豫公網安備 41072402000322號

豫公網安備 41072402000322號