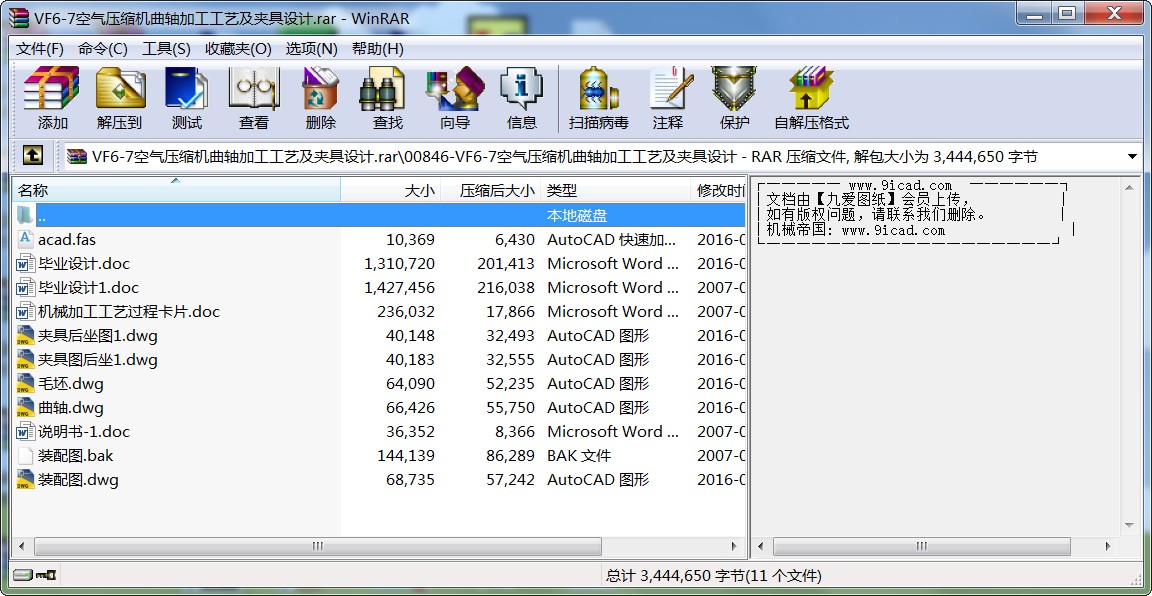

VF6-7空氣壓縮機(jī)曲軸加工工藝及夾具設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- VF6-7空氣壓縮機(jī)曲軸加工工藝及夾具設(shè)計(jì).rar

VF- 工藝及夾具設(shè)計(jì)

機(jī)械設(shè)計(jì)制造及其自動(dòng)化專(zhuān)業(yè)

學(xué)生:楊雷 指導(dǎo)教師:許紹華

摘要:機(jī)械制造業(yè)是一個(gè)國(guó)家技術(shù)進(jìn)步和社會(huì)發(fā)展的支柱產(chǎn)業(yè)之一,無(wú)論是傳統(tǒng)產(chǎn)業(yè),還是新興產(chǎn)業(yè),都離不開(kāi)各式各樣的機(jī)械裝備。而加快產(chǎn)品上市的時(shí)間,提高質(zhì)量,降低成本,加強(qiáng)服務(wù)是制造業(yè)追求的永恒主題。此篇論文主要內(nèi)容是對(duì)VF- 空壓機(jī)曲軸加工工藝路線(共包括53道工序)進(jìn)行的研究、設(shè)計(jì),其中包括了各道工序的加工方法,機(jī)床、刀具、夾具、輔具、量具的選擇,基準(zhǔn)面的選取,定位和夾緊方案的擬定;以及對(duì)第13、28道工序(粗車(chē)、精車(chē)曲拐)中所使用專(zhuān)用車(chē)模進(jìn)行了研究設(shè)計(jì)。此次研究的主要內(nèi)容在于如何使加工工序簡(jiǎn)單化、降低加工難度,從而達(dá)到提高產(chǎn)品加工效率,加快產(chǎn)品上市時(shí)間的目的。向著制造業(yè)所追求的主題進(jìn)發(fā)!

關(guān)鍵詞:曲軸 曲拐 夾具 工序卡

Abstract

Machinery manufacturing is a national technological progress and social development one of the pillar industries, whether in traditional industries, or emerging industries, and is inseparable from the wide range of machinery and equipment Speeding up the time to market, improve quality, reduce costs and enhance service is the eternal pursuit of manufacturing theme. Main content of this paper is to VF- air compressor crankshaft processing routes (including a total of 53 processes) for the research, design, which includes the processing of a process, machine, tool, fixture, ATD, Gauge choice datum selection, positioning and clamping of programming; and the right processes Road No. 13, 28 (crude cars, Accurately crankshaft), which use a special truck design. This study is the main content of how to simplify processes and reduce processing difficulties so as to improve processing efficiency, accelerate time-to-market goals. Toward manufacturing towards the pursuit of the theme!

Keywords : crankshaft fixture card process

目 錄

中文 摘要..........................................................

英文摘要...........................................................

緒 論.............................................................

第一章 VF-6/7空壓機(jī)曲軸工藝規(guī)程制定..........................

1.1 編制工藝應(yīng)注意的問(wèn)題........................................

1.2 曲軸加工工藝過(guò)程分析 .......................................

1.2.1曲軸零件功用、結(jié)構(gòu)特點(diǎn)和技術(shù)要求

1.3 曲軸的機(jī)械加工工業(yè)步驟制定

1.3.1曲軸特點(diǎn)及工藝措施

1.3.2毛坯形式選擇

1.3.3 定位基準(zhǔn)選擇

1.3.4 零件加工工藝路線

1.3.5 零件加工工藝路線分析

1.3.6 毛坯加工余量確定

1.3.7 選擇加工設(shè)備、刀具、量具及夾具等

1.3.8 切削用量選擇

第二章 工序計(jì)算過(guò)程.............................................

第三章 夾具設(shè)計(jì)

3.1 機(jī)床夾具概述

3.1.1工件的裝夾方法

3.1.2 夾具的作用、組成及分類(lèi)

3.2 粗精車(chē)曲拐夾具設(shè)計(jì)方案分析

3.2.1 切削力及加緊力計(jì)算

3.2.2 定位誤差分析

3.2.3 夾具設(shè)計(jì)及操作的簡(jiǎn)要說(shuō)明

結(jié)論......................................................

參考文獻(xiàn)...........

...

熱門(mén)關(guān)鍵詞:

熱門(mén)關(guān)鍵詞:

豫公網(wǎng)安備 41072402000322號(hào)

豫公網(wǎng)安備 41072402000322號(hào)